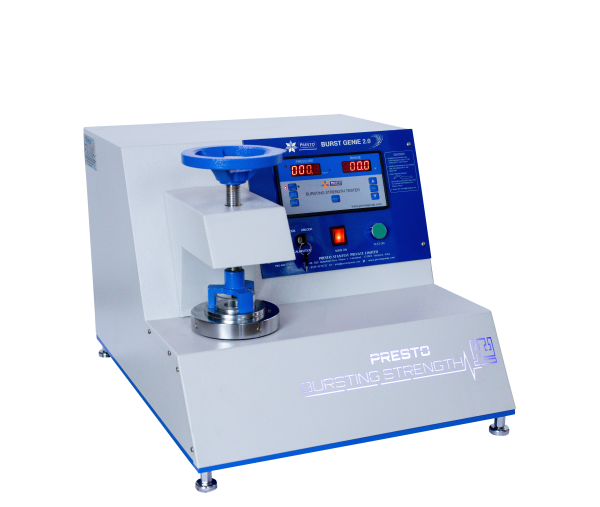

Just about Scenario where a faulty pipe bursts causing a sudden leak and potential damage to your property or harm your loved ones. This emphasizes the importance of ensuring the strength and integrity of your materials especially the ones designed 2 withstand internal pressure. You need to know that bursting strength testing plays a very important role in evaluating material performance, ensuring product quality and preventing catastrophic failures. In this guide, you can dive deep into the world of Bursting strength tester pneumatic. From pipes and hoses to packaging materials these testers are very important tools for evaluating your material strength and safety.

Understanding Bursting strength tester

At the core of burst testing lies the concept of burst strength. It is the ability of the material to withstand the internal pressure before rupturing. The parameter is very important for materials that are used in pressure vessels pipes and other products designed to contain fluids or gases. You must know that burst testing helps you identify material weaknesses and prevents potential accidents or failures caused due to ruptures, ensuring the safety and reliability of your products in real-world applications.

The power of Bursting strength tester pneumatic

You must know that Bursting strength tester hardness is the power of compressed air to gradually increase the pressure on a test sample until it reaches the breaking point. Some of the most important components like the pressure regulator, the chamber testing chamber and the data acquisition system are likely to work in tandem to control and monitor the pressure levels during the test. This will help you record the burst pressure data accurately and also ensure precise and reliable results. It is very important for quality control and product validation.

Advantages of Bursting strength tester pneumatic

The pneumatic bursting strength testers offers you plenty of benefits over alternative testing methods. It provides you a user-friendly operation and efficient testing process accommodating a huge range of materials with ease. The accurate and repeatable results obtained from the testers ensure confidence in material performance and safety. Furthermore, these testers also offer you a cost effective testing solution as compared to some alternative methods making them a great choice for you if you are prioritizing efficiency and value.

Applications across the industry

The versatility of Bursting strength tester makes them a perfect tool across different industries. In plastic and rubber manufacturing you can use it to test pipes and other products. In the food and beverage industry you can use the testers to ensure the integrity of the bottles containers enclosures. Similarly in the Pharmaceutical industry they play a very important role in testing vials for safety and quality assurance. Furthermore, pneumatic testers are used in research and development for developing new materials with improved burst strength. It can help you drive innovation and advancement in material science.

Choosing the right bursting strength tester

When choosing A pneumatic bursting strength tester there are different considerations that you need to consider. These include ensuring compatibility with the test material in terms of capacity and pressure range sample size and configuration. It includes features like data acquisition analytics capabilities for efficient testing and reporting.

In the pursuit of material performance and safety the bursting strength testers truly stand out like indispensable tools for evaluating the strength and integrity of your materials. It has the ability to accurately measure burst strength. It ensures the reliability and safety of products across different industries from manufacturing to packaging. By understanding the functionality advantages and applications of these testers you can ensure the quality and performance of your materials.