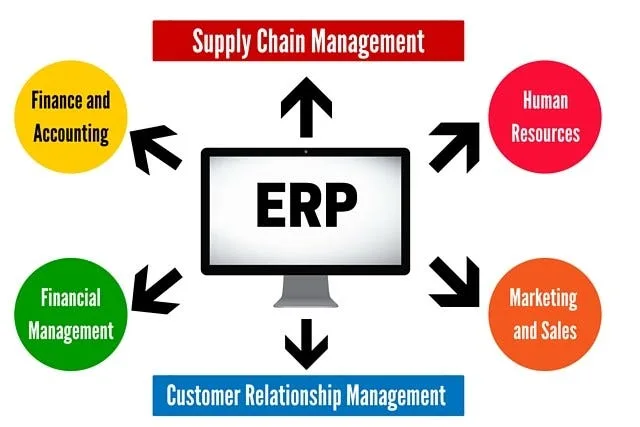

Enterprise Resource Planning (ERP) systems have become a cornerstone in modern ERP supply chain management. By integrating various functions, ERP systems provide a unified and real-time view of core business processes. This integration is crucial in supply chain management, where coordination and efficiency are key.

Historical Context: The Evolution of Supply Chain Management

The journey of supply chain management is marked by constant evolution. From rudimentary methods of tracking and logistics, the field has advanced significantly with the advent of digital technologies. This section explores how supply chain management has transformed over the years.

The historical evolution of supply chain management (SCM) is a fascinating journey, marked by significant advancements and innovations that have reshaped how businesses manage their operations. This transformation has been driven by changes in technology, economics, and business practices.

- The Early Beginnings:

- Pre-Industrial Revolution: Before the industrial revolution, supply chain management was rudimentary. Goods were produced and sold in small quantities, often within local markets. The concept of a supply chain was virtually non-existent, with most transactions being simple barter exchanges.

- The Industrial Revolution:

- Late 18th to Early 19th Century: The industrial revolution marked a turning point. Mass production techniques necessitated the development of more structured supply chains. The introduction of railways and steamships revolutionized transportation, enabling longer-distance trade.

- The Mid-20th Century:

- Post-World War II Era: This period saw the emergence of SCM as a distinct discipline. The focus shifted towards optimizing logistics to support mass production. Companies started to pay more attention to managing the flow of goods and materials to reduce costs and improve efficiency.

- The Advent of Computers:

- Late 20th Century: The introduction of computers and information technology brought a significant shift. Companies began to leverage software for inventory management, demand forecasting, and efficient resource allocation. This era introduced concepts like Just-In-Time (JIT) inventory and Total Quality Management (TQM), emphasizing efficiency and reducing waste.

- Globalization and Expansion:

- Late 20th to Early 21st Century: The globalization of markets expanded the scope and complexity of supply chains. Companies began sourcing materials globally, requiring a more sophisticated approach to manage these extended networks. Issues like cross-border logistics, currency fluctuations, and cultural differences became crucial factors.

- The Digital Age:

- 21st Century: The digital revolution further transformed SCM. Technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and blockchain have started to play a significant role. These technologies enable real-time tracking, predictive analytics, and greater transparency across the supply chain.

- Present and Future Trends:

- Sustainability and Resilience: The current focus in SCM is on sustainability and building resilient supply chains. The COVID-19 pandemic highlighted the need for supply chains that can adapt and respond to unforeseen disruptions. Additionally, there is a growing emphasis on reducing the environmental impact of supply chain activities.

- The Role of ERP:

- Integration of Technology: In the current landscape, Enterprise Resource Planning (ERP) systems have become integral in SCM. ERP systems help integrate various aspects of the supply chain, from procurement to distribution, providing a unified view and enhancing operational efficiency.

Understanding ERP Systems

At the heart of ERP systems are core features like inventory management, procurement, sales, and logistics. These systems integrate these disparate components into a cohesive whole, streamlining operations across the supply chain.

Benefits of ERP in Supply Chain Management

The adoption of ERP in supply chain management has led to remarkable improvements. Enhanced efficiency through automation, improved accuracy in data management, and better decision-making capabilities are just a few of the benefits. This section delves into how ERP systems optimize supply chain operations.

Case Studies: Successful ERP Implementations

Real-world examples of ERP implementations provide valuable insights into their impact. This section will explore a couple of case studies where ERP systems have significantly improved supply chain operations.

Challenges and Solutions in ERP Implementation

While ERP systems offer numerous benefits, their implementation comes with challenges. This part of the article will discuss common obstacles and strategies to overcome them, ensuring successful ERP integration.

Future Trends in ERP and Supply Chain Management

The future of ERP in supply chain management looks promising, with emerging technologies like AI and IoT playing a significant role. This section will discuss these technologies and offer predictions for the future.

Conclusion

ERP systems are revolutionizing supply chain management. Their ability to integrate and streamline operations leads to enhanced efficiency and decision-making, propelling businesses towards greater success.